The Benefits of Metalworking Fluids for Refractory Metal Processing

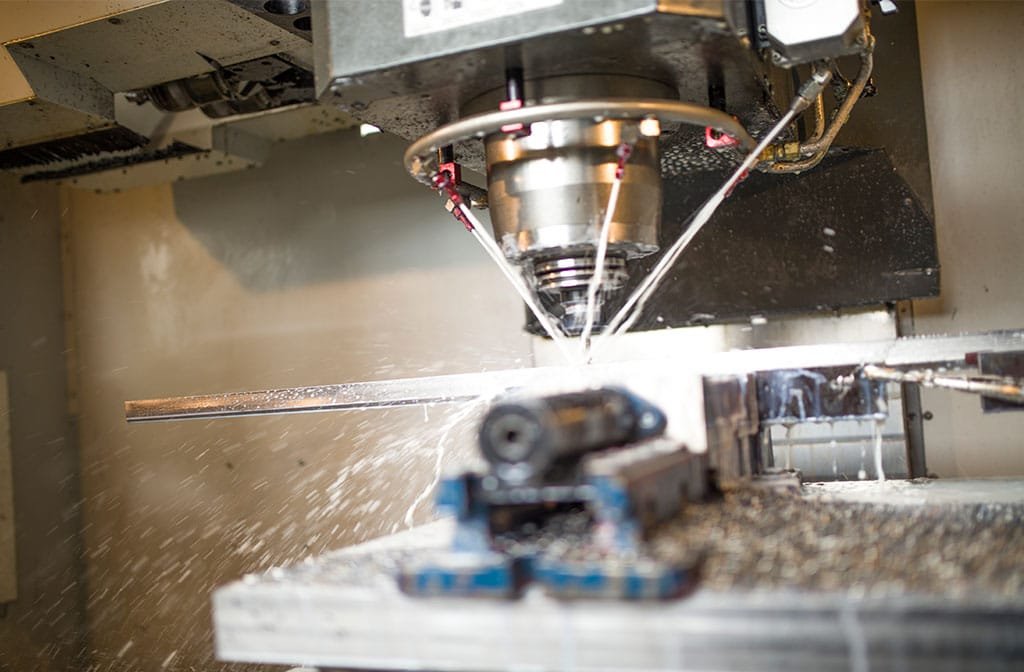

Refractory metal metalworking fluids are engineered synthetic fluids formulated to enhance and extend tool life by improving surface finish and removing destructive friction at the contact point between the tool and the workpiece. Premium-quality metalworking fluids provide machine operations with a safe solution for low-risk, effective machining, forming, and shaping of complex substrates. Workpiece quality